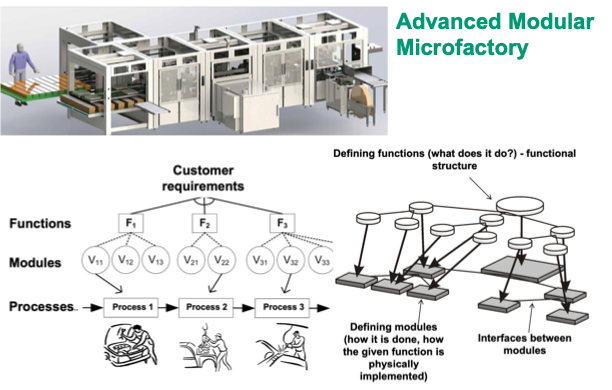

AMMF – Advanced Modular Microfactory

- Advanced – latest engineering, manufacturing and digital approaches and technologies are used

- Modular – strict modular architecture, where each module fulfills a precisely defined function and the modules are interconnected by standardized interfaces

- Microfactory – a small, flexible, reconfigurable, efficient and mobile factory that can be rented as a service

A microfactory is a small-scale manufacturing facility that is capable of producing a variety of products using advanced technologies and automation. It is typically designed to be flexible and adaptable, so it can quickly switch between different products and production processes. Micro factories are often used for small-batch production or custom manufacturing, and can be located in urban areas, closer to the end customers.

Micro factories are different from traditional factories in that they are smaller, require less space and resources, and can be set up more quickly and at a lower cost. They typically use digital technologies such as 3D printing, computer-aided design (CAD), and robotics to enable rapid prototyping, customization, and agile manufacturing.

A microfactory is a small-scale manufacturing facility that is capable of producing a variety of products using advanced technologies and automation. It is typically designed to be flexible and adaptable, so it can quickly switch between different products and production processes. Micro factories are often used for small-batch production or custom manufacturing, and can be located in urban areas, closer to the end customers.

Micro factories are different from traditional factories in that they are smaller, require less space and resources, and can be set up more quickly and at a lower cost. They typically use digital technologies such as 3D printing, computer-aided design (CAD), and robotics to enable rapid prototyping, customization, and agile manufacturing.

Microfactories are designed to be modular (1 function = 1 module + standardized interfaces for module integration), with components that can be easily reconfigured or replaced to accommodate changes in production processes or product requirements. Modularization is an approach to designing products or systems by breaking them down into smaller, standardized, and interchangeable components or modules.

Key elements of a microfactory

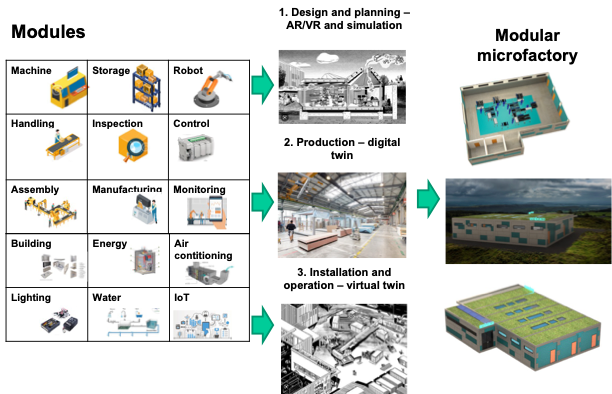

- Production Equipment: This includes the machines and tools needed for manufacturing, such as 3D printers, CNC machines, assembly stations, and quality control systems.

- Material Handling Systems: Microfactories typically use automated systems for material handling and logistics, such as robots and conveyors, to transport materials and finished products between different workstations and storage areas.

- Digital Tools: Microfactories often incorporate digital tools such as simulation software, data analytics, and virtual reality tools to optimize production processes and monitor quality control.

- Modular Design: Microfactories are designed to be modular, with components that can be easily reconfigured or replaced to accommodate changes in production processes or product requirements.

- Scalability: Microfactories can be scaled up or down depending on demand, making them suitable for small-batch production and prototyping as well as larger-scale production runs.

- Energy Efficiency: Microfactories are often designed to be energy-efficient, using advanced manufacturing technologies that consume less energy and reduce waste.

- Integration with Supply Chains: Microfactories can be integrated into supply chains to provide localized production and faster response times to changing market demands.

- Business models od Economy of Sharing and Manufacturing as a Service.

This concept combines all the current important transformational trends in manufacturing – local, green, customized, flexible, efficient manufacturing as a service.

Benefits of AMMF:

- Transformation of the economy from automotive to non-automotive

- Increasing competitiveness and growth of domestic producers

- Creation of a base for designing and exporting micro factories – growth of GDP and employment

- Reducing regional differences in Europe

- Positive impact on the green and circular economy (reconfiguration, recycling, mobility, local production)

- Elimination of regional differences in the world and reduction of social problems

- Increasing the level of education of young people in Europe

- Re-localization and customization (local production near the consumer)

- Gradually building a factory without a large investment (suitable for SMEs, large corporations have their supply systems for building large factories)

3 Elements of AMMF:

1.Technological – machines, workplaces, robots, control systems, material handling devices, control and control workplaces

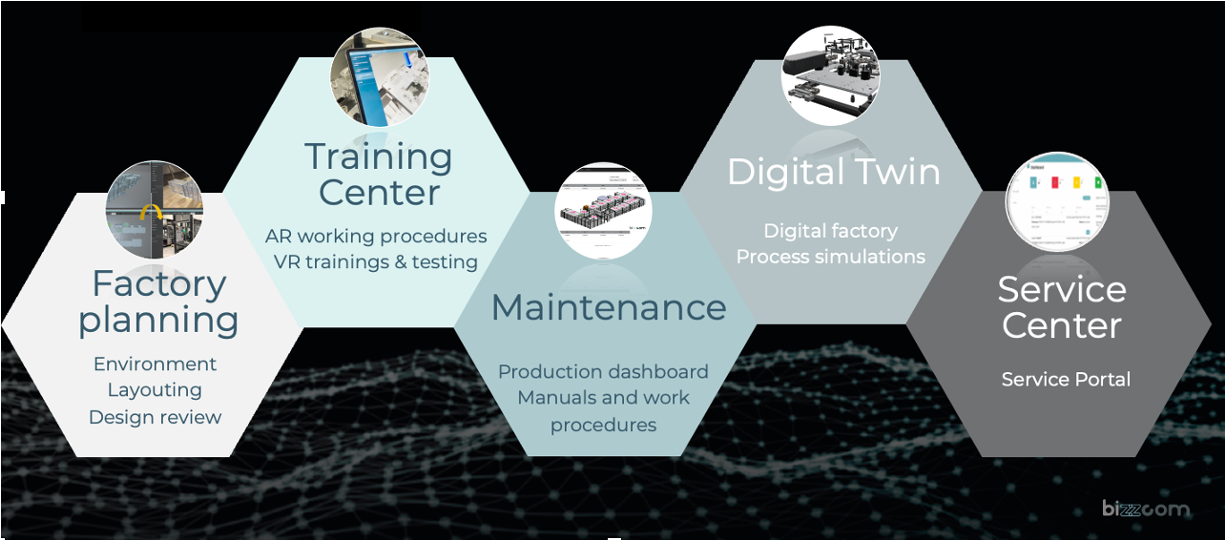

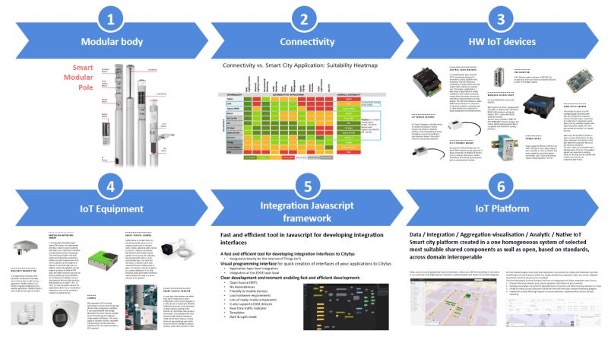

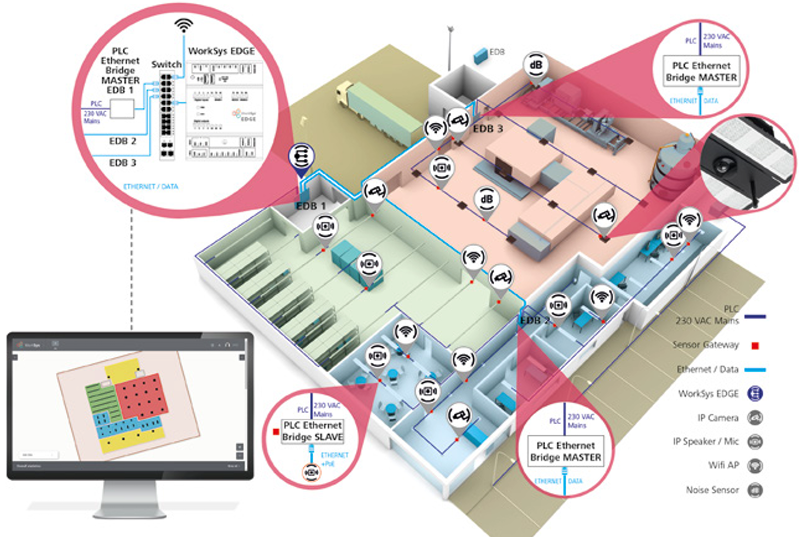

2.Digital, analytical and control modules – open platform, layers, interoperability, connections, application modules

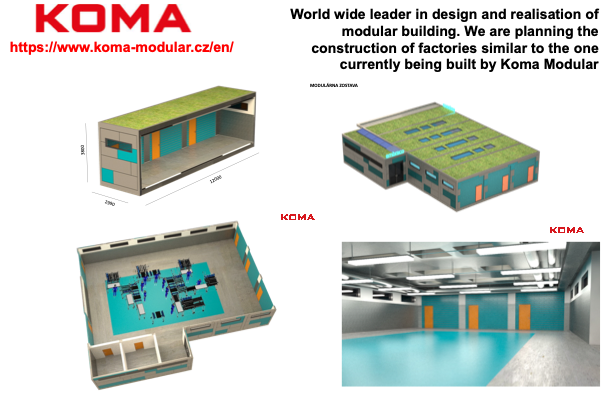

3.Building modules – the building and its elements (energy, air conditioning, water, sanitation, light, IT, etc.) – everything designed and manufactured with a circular economy in mind – no concrete monoliths.

Our experience:

Click here – Building the Airport in Senegal by KOMA Modular

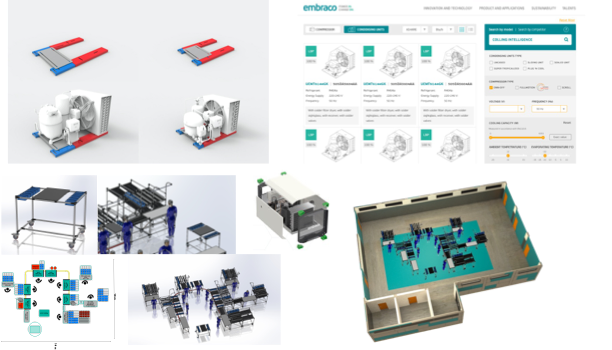

KOMA + Inovato project – modular product (condensing unit), digital configurator, modular factory

Click here to see the project of modular condensing unit and modular manufacturing system

Bizzcom modular manufacturing line and digital design and development system

Kinazo design – first 3D printed modular eBike (concept of customized flexible modular factory)

https://kinazo-design.com/e-bike/

Modular digital platform – https://online.worksys.space/

Manufacturing Control Modules

Notus Powersonic Modular System – https://www.svecgroup.sk/?lang=en

AI in visual inspection – https://www.inspector-ai.solutions/

Modular robots – https://spinbotics.com/

Our project activities:

1. Preparatory Phase – Current State Analysis

2. Project Management and Organisation

3. Methodology of Modular Microfactory Design

4. Testing and Integration of Existing Solution to whole System

5. Design of Macro Modules

6. Design and Development of Modular Microfactory Planning System

7. Testing and Validation of Modular Microfactory

8. Preparation of experts

9. Projects in industry and consulting

10. Technological incubator for manufacturing startups

11. Business development and marketing

Contact Person: Ján Košturiak, kostur@ipaslovakia.sk